Here are some showcases of our cost-effective and tailored sheet metal processing equipment for our clients:

-

- Automated Production Lines for Sheet Metal Processing Enterprises A well-known sheet metal enterprise, in order to overcome the bottlenecks of traditional production, required the development of a fully automated production line covering the entire process of blanking – punching – transfer – bending. The goal was to reduce costs, improve efficiency, and enhance processing stability. Find Out More

-

- Aluminum Veneer Curtain Wall for Carsion Cooperation is built on trust, and quality forges reputation. Recently, Deratech Machine Tool was awarded the title of “Outstanding Supplier of 2024” by Guangdong Carsion Metal Technology Company. This honor fully affirms Deratech's outstanding performance in equipment quality, technical capability, and service assurance, demonstrating the high level of recognition our products receive from customers. Find Out More

-

- Second Purchase of Bending Unit by DSK Elevator Co. It is recognized as a National High-Tech Enterprise and a “Specialized, Refined, Distinctive, and Innovative” enterprise in Sichuan Province. Through technological innovations - such as intelligent elevator payment systems, fault early-warning, and standardized factory production - the company has maintained a leading position in the industry and has established a long-term strategic partnership with Deratech Machine Tool. Find Out More

-

- A New Breakthrough in Large-Tonnage CNC Servo Electric Press Brakes Traditional large-tonnage electric press brakes often face a core challenge during processing: their ballscrew drive guidance typically relies on sliding guides. However, when the press brake is in operation, the side-frame throat deforms under load – and the greater the bending force, the greater the deformation. Find Out More

-

- Robotic Bending Unit Enhances Quality and Efficiency in the Aluminum Panel Industry Fujian Nan Aluminum Sheet & Strip Company, a subsidiary of Nanping Aluminium, has established a complete aluminum sheet and strip industry chain (aluminum casting & rolling - aluminum sheets & strips - coated panels). Its annual production capacity covers 75,000 tons of high-precision aluminum sheet and strip and 1 million m² of curtain wall aluminum panels. Find Out More

-

- Multiple Deratech Solutions Empower Kitchenware Industry Upgrade in Shanxi Recently, a kitchenware manufacturer in Shanxi, China once again chose Deratech to build a more complete and efficient intelligent production line. In this cooperation, Deratech provided a fully customized set of advanced processing equipment covering multiple stages of production - including stamping, bending, and grooving - to create a highly efficient production line that integrates both intelligence and automation. Find Out More

-

- Robotic Bending Cell Provided To Swiss Company The client places great emphasis on the upgrading and iteration of their metalworking machinery, incorporating advanced technologies to enhance the automation capabilities of their production equipment. Their objective is to improve production processes, integrate production models, and transform their existing production resources into a world-class factory that excels in energy efficiency, environmental sustainability, high efficiency, and automation. Find Out More

-

- Robotic Bending Cell Exported To Thailand The automated robotic bending cell is equipped with an automatic and fast gripper changing device. It also features a 7-meter walking axis that significantly expands its range of motion, enabling it to handle large-sized sheet metals effectively. Find Out More

-

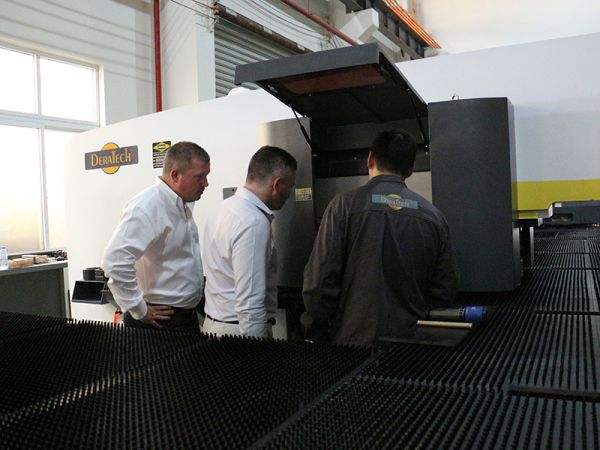

- CNC Metalworking Machines Accepted By UK Customer On August 28th, Mr. De Vooght Nico, the General Manager of DERATECH Belgium, accompanied a British client to visit and inspect Shanghai DERATECH CNC Machine Co., Ltd. They performed acceptance tests on metalworking machinery such as CNC press brake, CNC hydraulic shear, and CNC turret punching machine. Find Out More

-

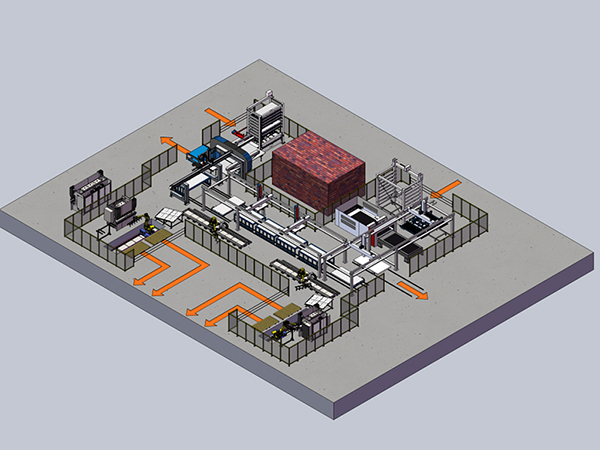

- Metalworking Automation Solution For Transformer Manufacturer The customized metalworking automation solution for Jiangsu Huapeng Transformer Co., Ltd., has successfully passed acceptance and are now fully operational. The system is primarily used in the production and manufacturing of single-phase transformer oil tank casings. Find Out More

-

- Robotic Bending Cell For Home Appliance Manufacturer This home appliance supplier produces a wide range of products with complex processes. The existing sheet metal machinery cannot meet their needs. Therefore, the customer requires highly automated metal fabrication machines that can reduce costs, improve responsiveness, and enhance adaptability for new products. Find Out More

-

- Robotic Bending Cell Used In Switchgear Manufacturing By the end of 2021, the customer's company underwent a comprehensive upgrade in industrial automation. We customized three sets of specialized robotic bending cells for the high and low voltage switchgear industry, which were officially put into operation in April 2022. Find Out More

-

- Robotic Bending Cell For Kitchen Equipment Manufacturer A kitchen equipment manufacturer in Shenzhen required customized and irregularly-shaped metal workpieces to be processed in a cost-effective, informationized and intelligent manner. However, common sheet metal equipment manufacturers couldn't meet their requirements. Find Out More

-

- CNC Punch-Laser Combination Machine Used In Structural Steel Fabrication DERATECH has provided TSK INDUSTRIES SDN BHD in Malaysia with a CNC punch-laser combination machine. Recently, the machine successfully passed the acceptance inspection and was put into operation at their factory in Johor Bahru, Malaysia. Find Out More

-

- Robotic Bending Cell For Automotive Industry A customer in the automotive parts industry in Qingdao emphasizes the use of advanced technology and equipment to improve product quality through practical actions. In March 2020, this customer partnered with DERATECH to introduce a mobile robot bending unit for processing large sheet metal parts. Find Out More

-

- Flexible Bending Cell For Automotive Repair & Maintenance The automotive repair & maintenance equipment industry often uses large workpieces similar to channel steel. These types of workpieces require 3-5 people to complete tasks such as loading, bending, and stacking. Additionally, the size and dimensional specifications of the finished products vary greatly, making precision control difficult. Find Out More