We will gladly assist you in making the right decision to achieve your business goals

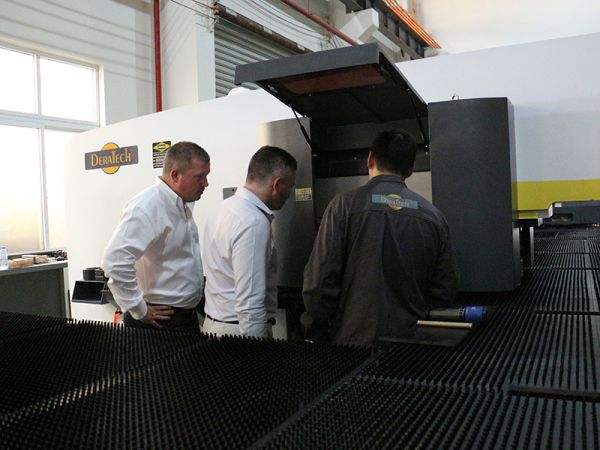

A kitchen equipment manufacturer in Shenzhen required customized and irregularly-shaped metal workpieces to be processed in a cost-effective, informationized and intelligent manner. However, common sheet metal equipment manufacturers couldn't meet their requirements.

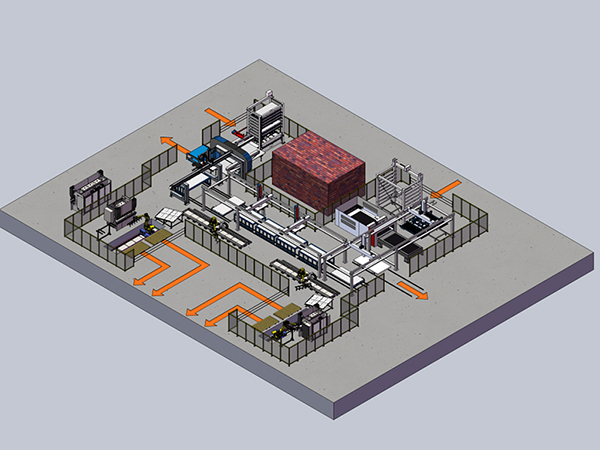

DERATECH provides the customer with a tailor-made automated robotic bending cell, which consists of three CNC hybrid press brakes, two sets of FANUC robots, and two horizontal auxiliary axes.

The automated robot bending production line was thoroughly tested and commissioned in October 2020 and has been operational ever since. As a result, the client's productivity has doubled with a substantial increase in output capacity. Previously, it took a team of 5-6 people to complete the production of large sheet metal pieces like steamers and woks. However, with the new production line, only one person is now needed, and they can finish the same amount of work within half a day as before. Additionally, the consistency of workpiece dimensions meets the welding requirements for future automation, resulting in significant savings in both time and labor costs.