We will gladly assist you in making the right decision to achieve your business goals

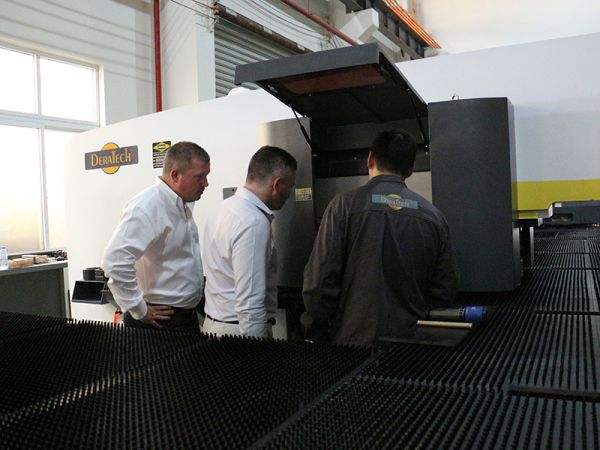

Sichuan DSK Elevator Manufacturing Company focuses on the field of building retrofit elevators. It is recognized as a National High-Tech Enterprise and a “Specialized, Refined, Distinctive, and Innovative” enterprise in Sichuan Province. Through technological innovations - such as intelligent elevator payment systems, fault early-warning, and standardized factory production - the company has maintained a leading position in the industry and has established a long-term strategic partnership with Deratech Machine Tool.

As a long-term partner, Deratech Machine Tool has provided multiple CNC machines to DSK in recent years.

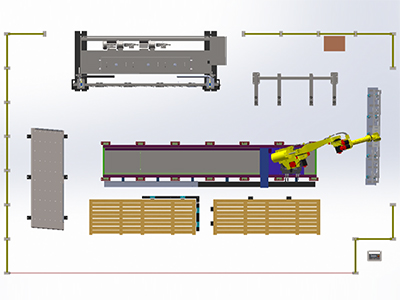

At the beginning of 2023, due to a surge in orders, traditional manual bending capacity could no longer meet production requirements. After learning about Deratech's industry cases in robotic bending, DSK sought to address its sheet bending capacity needs through Deratech's robotic bending sell. Upon receiving DSK's request, Deratech's technical team quickly customized a solution: they designed a multi-purpose gripper fixture to overcome the challenge of adapting one gripper to multiple types of workpieces, and tailored a robotic bending cell for the customer, which was promptly delivered and put into operation. This bending cell has now been in use for over a year, significantly reducing workers' labor intensity, saving manpower, and improving capacity - with a zero-failure rate.

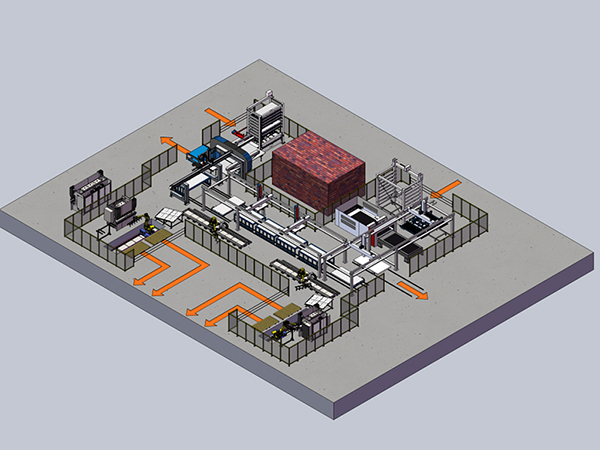

In October 2024, coinciding with DSK's product model upgrade and capacity expansion, DSK reinforced its partnership with Deratech by placing a repeat order for another robotic bending cell.

Deratech specially customized a centering loading/unloading table, a gravity centering table, and robotic grippers to meet the process requirements of DSK Elevator's products. The solution adopts Deratech's TAM-S series high-precision press brakes, equipped with the latest CT12 CNC system from Switzerland's Cybelec.

This bending cell can automatically complete the entire process from raw material to finished bent product. Workers only need to place sheet materials on the loading table and remove the stacked finished products from the unloading table. In addition, the bending cell is connected to the customer's production management system, facilitating production management and trace ability.

From the first bending cell in 2023 to the repeat purchase in 2024, DSK's choice demonstrates the stability and customization capability of Deratech's robotic bending cells. The newly delivered equipment has completed installation and commissioning and is now in production, successfully solving the bending challenges of “multiple workpiece types and large size variations.” It has been highly recognized by the customer.

Deratech not only provides robotic bending cells, but also offers a wide range of automation products, including laser material storage systems, CNC turret punch press loading/unloading solutions, and flexible sheet metal production lines.