We will gladly assist you in making the right decision to achieve your business goals

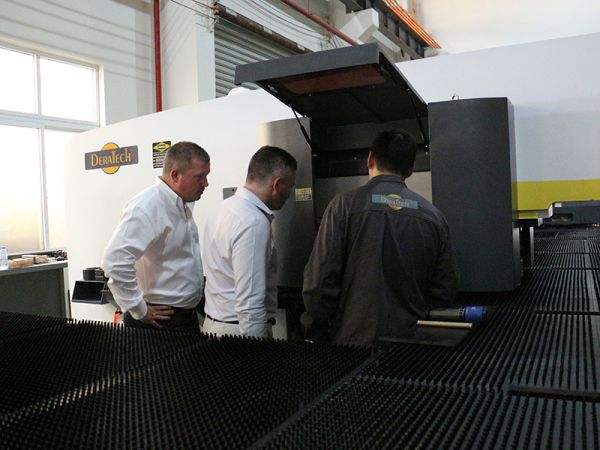

DERATECH has provided TSK INDUSTRIES SDN BHD in Malaysia with a CNC punch-laser combination machine. Recently, the machine successfully passed the acceptance inspection and was put into operation at their factory in Johor Bahru, Malaysia.

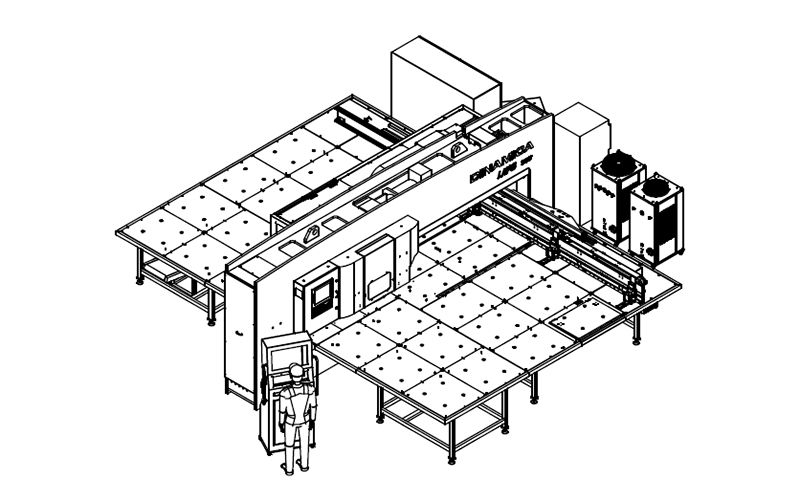

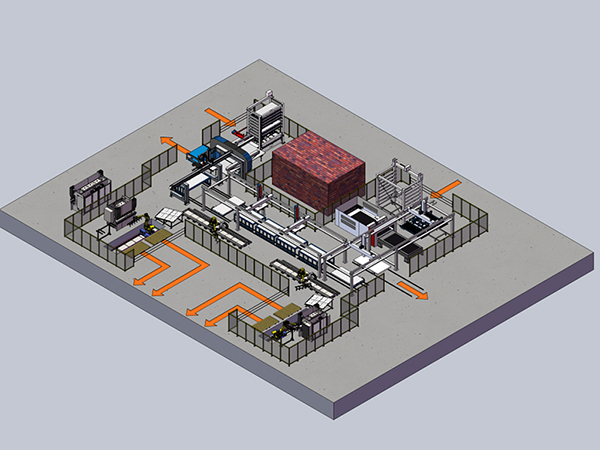

This equipment offers a generous processing stroke of X: 2500mm and Y: 1750mm, making it suitable for handling large-sized sheet metals as required by the customer. By integrating punching and laser cutting functions, the machine eliminates the need for secondary positioning during processing, resulting in significant improvements in efficiency and accuracy, as well as reduces the occupied space and turnover area by over half, thereby enhancing site utilization.

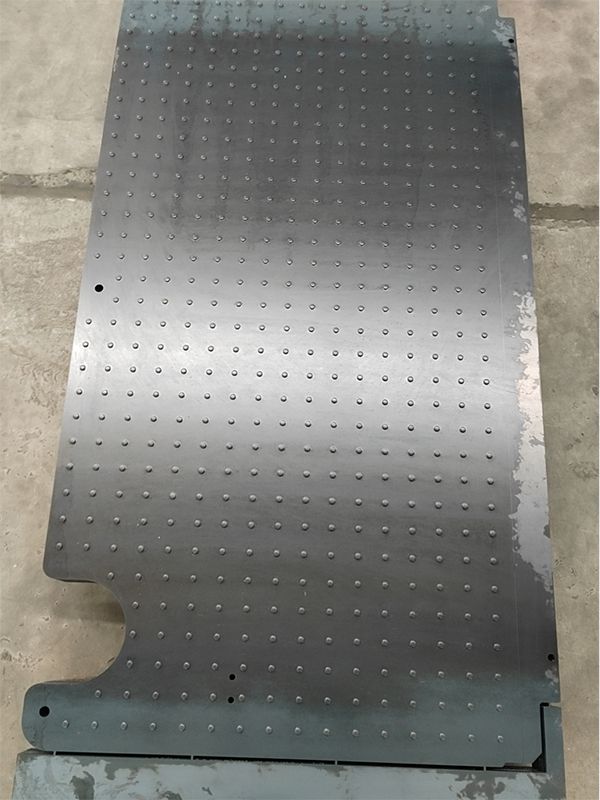

The image above showcases the processed parts of the customer. These sheet metal parts have been manufactured with a thickness of 4mm and involve multiple processes to achieve their desired convex shapes. The manufacturing process for these parts is intricate due to the irregular contours involved. To address this complexity, laser cutting has been employed, eliminating the need for custom non-standard punching molds. This not only streamlines production but also reduces costs effectively. Furthermore, our designer has dedicatedly created a stamping mold specifically tailored to meet the customer's precision requirements. This mold has been thoroughly validated to ensure it meets the desired standards. Additionally, by refining our manufacturing process, we have successfully minimized the deformation of sheet metal during processing.