We will gladly assist you in making the right decision to achieve your business goals

Fujian Nan Aluminum Sheet & Strip Company, a subsidiary of Nanping Aluminium, has established a complete aluminum sheet and strip industry chain (aluminum casting & rolling - aluminum sheets & strips - coated panels). Its annual production capacity covers 75,000 tons of high-precision aluminum sheet and strip and 1 million m² of curtain wall aluminum panels. The company's product technical indicators have reached an internationally advanced level and are widely applied in high-end architectural fields such as curtain walls and interior ceilings.

Curtain wall aluminum panels are a typical customized product, characterized by “a wide variety of types, large differences in dimensions, and a high proportion of irregular parts.” With the increase in customer orders, traditional manual bending methods can no longer meet production needs. The customer learned that Deratech has many successful cases of robotic bending applications in related industries, and hopes to use Deratech's robotic bending cell to address the challenges in sheet production, such as the wide variety of panel types and large dimensions, which are difficult to handle by traditional manual operations.

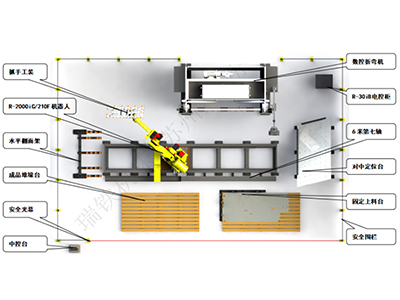

In response to the requirements of Fujian Nan Aluminium Sheet & Strip Company, Deratech provided a specially customized system including loading/unloading tables, a gravity centering station, and a robotic quick-change gripper system, fully meeting the customer's diversified process needs. The bending process is performed using Deratech's TAM-S series high-precision press brake, equipped with the reliable Swiss Cybelec CT15win six-axis CNC system and a FANUC 210 robot. This bending cell enables full automation of the entire production process - from raw material to finished bent parts. Operators are only required to perform basic loading/unloading supervision at the workstation. Furthermore, the bending cell's digital information is integrated with the customer's production management system, facilitating production control and information tracking.

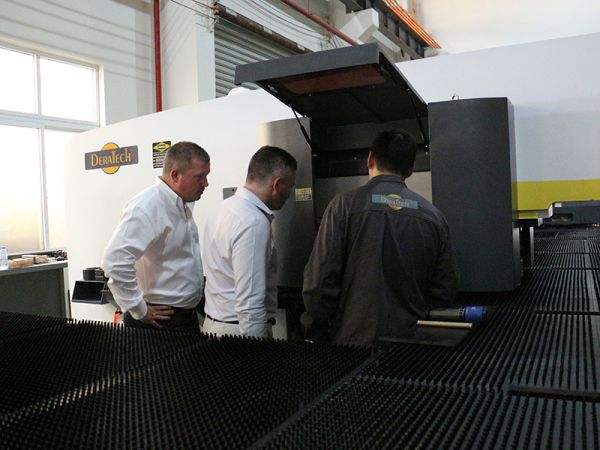

With Deratech's efficient and rapid installation, commissioning, and training, the customer's robotic bending cell was put into production in a very short time. This robotic bending cell is yet another successful case of Deratech's robotic bending solutions in the curtain wall industry. It effectively solved the customer's challenges of handling a wide variety of panel types and large product dimensions during the bending process, and has received high recognition from the client!

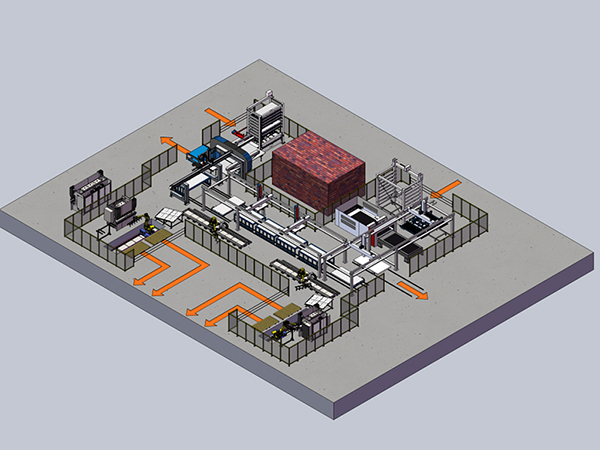

In addition to its widely applied robotic bending cells, Deratech also provides a broad range of automation solutions, such as flexible sheet-metal processing production lines, laser tower storage systems, and press automation loading/unloading systems. With numerous proprietary intellectual property rights and extensive project experience, Deratech is able to deliver more value-added products and services to customers both in China and abroad.