We will gladly assist you in making the right decision to achieve your business goals

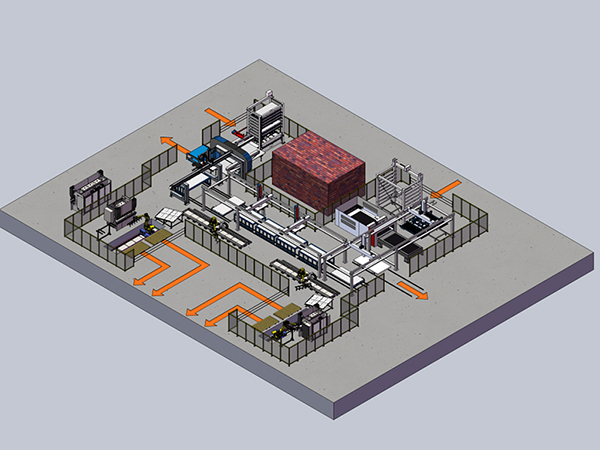

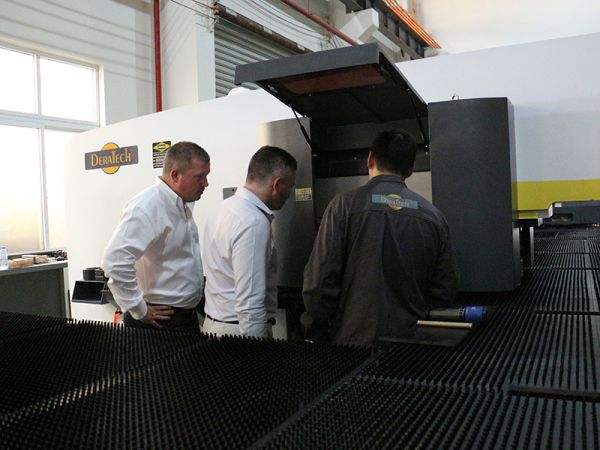

A customer in the automotive parts industry in Qingdao emphasizes the use of advanced technology and equipment to improve product quality through practical actions. In March 2020, this customer partnered with DERATECH to introduce a mobile robot bending unit for processing large sheet metal parts.

Based on feedback from the Qingdao customer, the current market in the automotive parts industry can be divided into two levels:

- Conventional automotive parts processing factories, facing a shortage of new orders and a decline in orders from existing customers, leading to operational difficulties.

- Automotive parts processing factories that prioritize higher processing quality and rapid delivery, experiencing an increasing volume of orders.

To meet the need for capacity upgrades, the customer introduced a robotic bending cell from DERATECH for the bending processing of small parts, replacing the traditional outsourcing stamping process.

This unit consists of a CNC press brake, a FANUC six-axis robot, and a set of horizontal 7th-axis.

Thanks to the DERATECH intelligent production line, the Qingdao customer has experienced remarkable improvements in their manufacturing processes. By reducing transportation steps and optimizing production flow, the customer has witnessed enhanced efficiency and higher product quality. As a result, they have managed to save approximately one million yuan in annual labor costs, leading to significant economic benefits.

"DERATECH intelligent production unit is highly stable, efficient in processing, and ensures product qualification. We have now implemented multiple shifts," exclaimed the production department.