We will gladly assist you in making the right decision to achieve your business goals

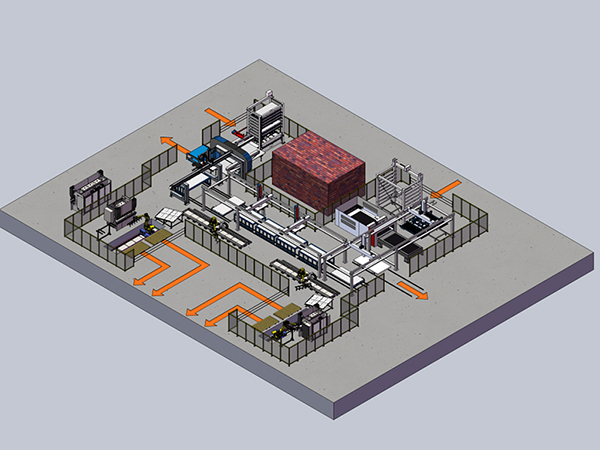

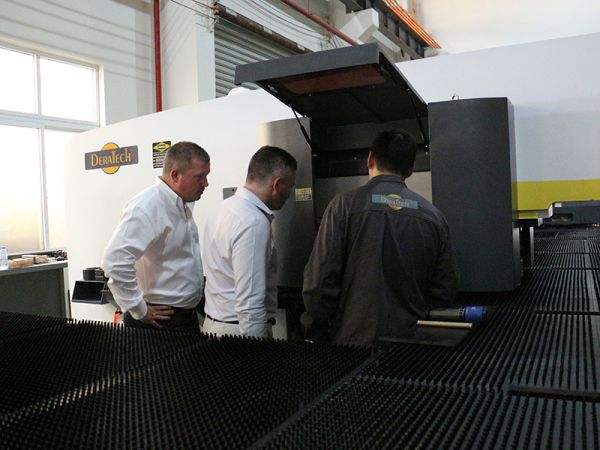

This home appliance supplier produces a wide range of products with complex processes. The existing sheet metal machinery cannot meet their needs. Therefore, the customer requires highly automated metal fabrication machines that can reduce costs, improve responsiveness, and enhance adaptability for new products.

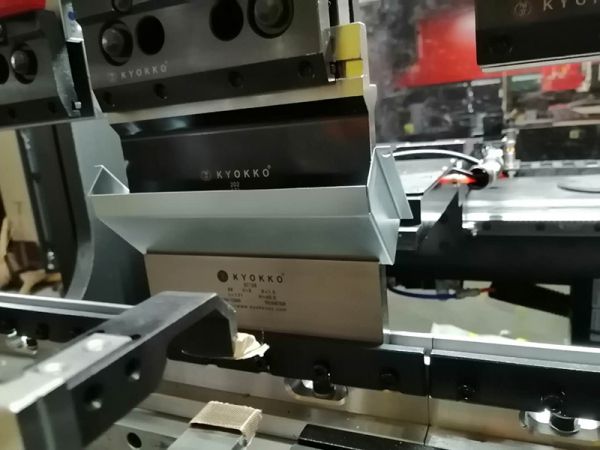

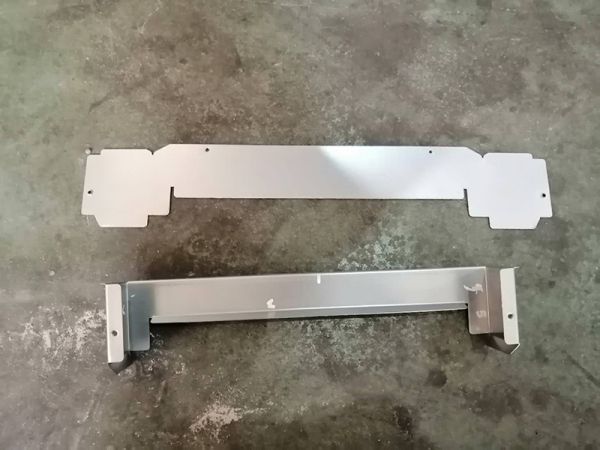

This intelligent robotic bending cell combines a CNC press brake and robots through a PLC system, enabling automatic grabbing, alignment, multiple process bending, flipping, and stacking of sheet metal. During continuous operation, it can be operated without human intervention, significantly reducing the labor intensity of manual operations. By completing multiple processes in one step and reducing intermediate steps, it improves real-time production efficiency, helping customers achieve lean production.

The unit is equipped with the FANUC R-200id/8F robot, which features a high-performance arm with a high payload capacity, faster operating speed, and higher efficiency. Combined with FANUC's dedicated software for sheet metal bending, each processing step can yield tangible benefits for customers.

"The DERATECH automation equipment we purchased, along with their one-stop solution, have greatly improved our efficiency and led to a significant increase in profitability compared to before. It has effectively solved the problems of long production cycles and low processing efficiency, bringing us great convenience," the customer praised.